If the last three years have taught us anything, it’s that "normal" is a setting on a washing machine, not a state of the global supply chain. As we close out 2025, I want you to take a breath. Look at your operations. You’ve likely survived the tariff hikes, the "friend-shoring" shifts, and the raw material scrambles that defined the mid-20s. But survival isn't the goal anymore, mastery is.

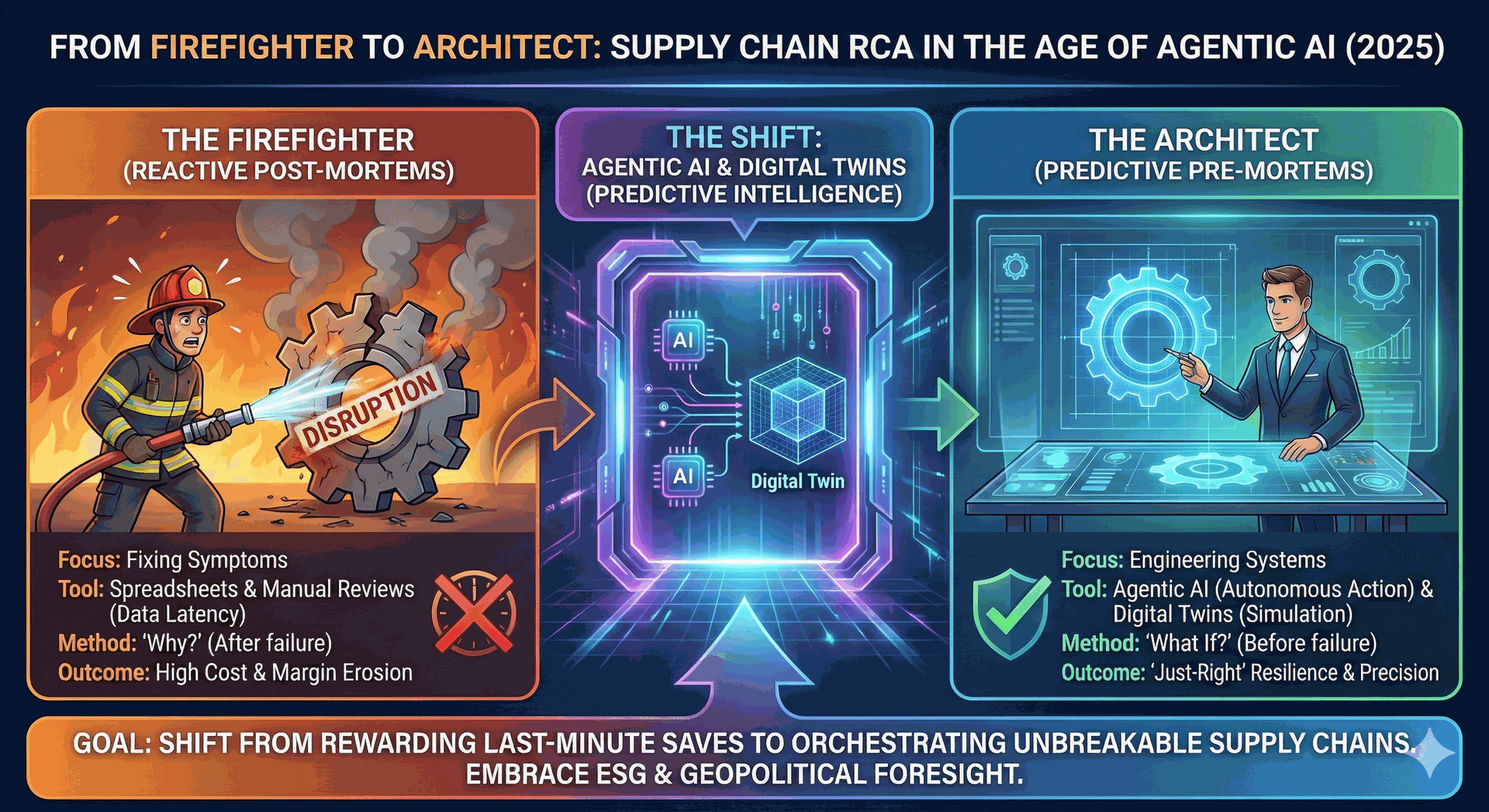

For years, business owners have treated Root Cause Analysis (RCA) as a post-mortem exercise: something broke, we scrambled to fix it, and then we sat in a conference room asking "Why?" five times until we blamed a supplier or a spreadsheet error.

That approach is obsolete. In late 2025, RCA is no longer about looking backward at what went wrong; it’s about looking forward at what could go wrong and stopping it before it manifests. It’s the difference between being a firefighter and being an architect.

Here is where we stand, and how you can leverage the new era of RCA to build an unbreakable business.

1. The Landscape: The Death of the "Post-Mortem"

For decades, the primary challenge in RCA was data latency. By the time you discovered the root cause of a stockout, perhaps a Tier-3 supplier missing a compliance check, the damage was already done. The customer was lost; the margin was eroded.

Today, the landscape has shifted from reactive to cognitive. The primary challenge for business owners in 2025 isn't finding data; it's filtering the signal from the noise. We are drowning in alerts from IoT sensors, weather satellites, and geopolitical news feeds.

The "Just-in-Time" models of the 2010s broke under pressure, and the "Just-in-Case" hoarding of 2023 destroyed cash flow. We have now settled into the era of "Just-Right" Resilience, but this requires a level of precision that human analysis alone cannot achieve. If you are still relying on spreadsheets to find the ghost in the machine, you are fighting a digital war with analog weapons.

2. The Innovation: Agentic AI and the "Pre-Mortem"

The game-changer of 2025 has been the rapid maturation of Agentic AI. Unlike the generative AI of a few years ago that could only summarise text, Agentic AI can take action.

In the context of RCA, this is revolutionary. We now have systems that don't just flag a delay; they autonomously trace the digital thread back to the source, be it a labor strike in a specific port or a raw material shortage in Brazil, and propose (or even execute) a rerouting strategy.

Recent reports highlight that Agentic AI is becoming a business imperative for operational improvements. These agents bridge the gaps between siloed systems, acting as the "connective tissue" that human teams used to struggle to maintain.

Furthermore, the integration of Digital Twins has allowed us to move from post-mortems to pre-mortems. We can now simulate a tariff hike or a supplier bankruptcy in a virtual environment to find the root cause of a potential collapse. This "predictive resilience" is saving companies millions by identifying weak nodes before they ever crack. Recent findings on digital twins suggest they are reshaping the very logic of recovery, turning resilience into a measurable science rather than a vague goal.

3. Future Outlook: The "Human-in-the-Loop" Revolution (2026-2027)

So, where do we go from here? If AI is finding the root causes, what is your role?

As we look toward 2026, the role of the business owner and supply chain leader is shifting from operator to orchestrator. Your job is to define the parameters within which these AI agents operate.

We are also seeing a massive shift in what we consider a "root cause." It’s no longer just mechanical or logistical. The emerging frontier is ESG (Environmental, Social, and Governance). With tightening regulations globally, a carbon emission violation in your Tier-4 supply base is now a critical failure point.

According to KPMG's 2025 trends, Scope 3 emissions and ethical sourcing are moving from "nice-to-have" to operational mandates. The root cause of your next disruption might not be a missing part, but a regulatory fine due to a supplier's poor labor practices.

Additionally, geopolitical friction remains a constant variable. McKinsey’s late 2025 risk analysis notes that tariffs and trade reshuffles are forcing companies to fundamentally rethink their footprint. The "root cause" of high costs next year may simply be having your manufacturing in the wrong hemisphere.

Conclusion: Stop Fixing Symptoms

My advice to you as we head into a new year is simple: Stop rewarding firefighting.

If your team is constantly praised for saving the day at the last minute, you have a culture problem. You should be rewarding the boring, quiet days where nothing went wrong because the root causes were identified and neutralised months ago.

Leverage the new tools. Trust the data. But most importantly, keep your hand on the wheel. The technology provides the roadmap, but you provide the moral and strategic compass.

The Next Step for You: Outline the key questions you need to ask your team to uncover hidden vulnerabilities before they become headlines.

I used Nano bana to generate the images and Info Graphic