If there is one thing I have learned over the many years in this game, from the paper-pushing days of the early 90's to the cloud revolutions of the 2010's, it is that procurement is cyclical. We oscillate between chasing the "next big shiny object" and realising that the shiny object doesn't work if the engine room is full of rust.

As we close out December 2025, I sense a collective exhale across our profession.

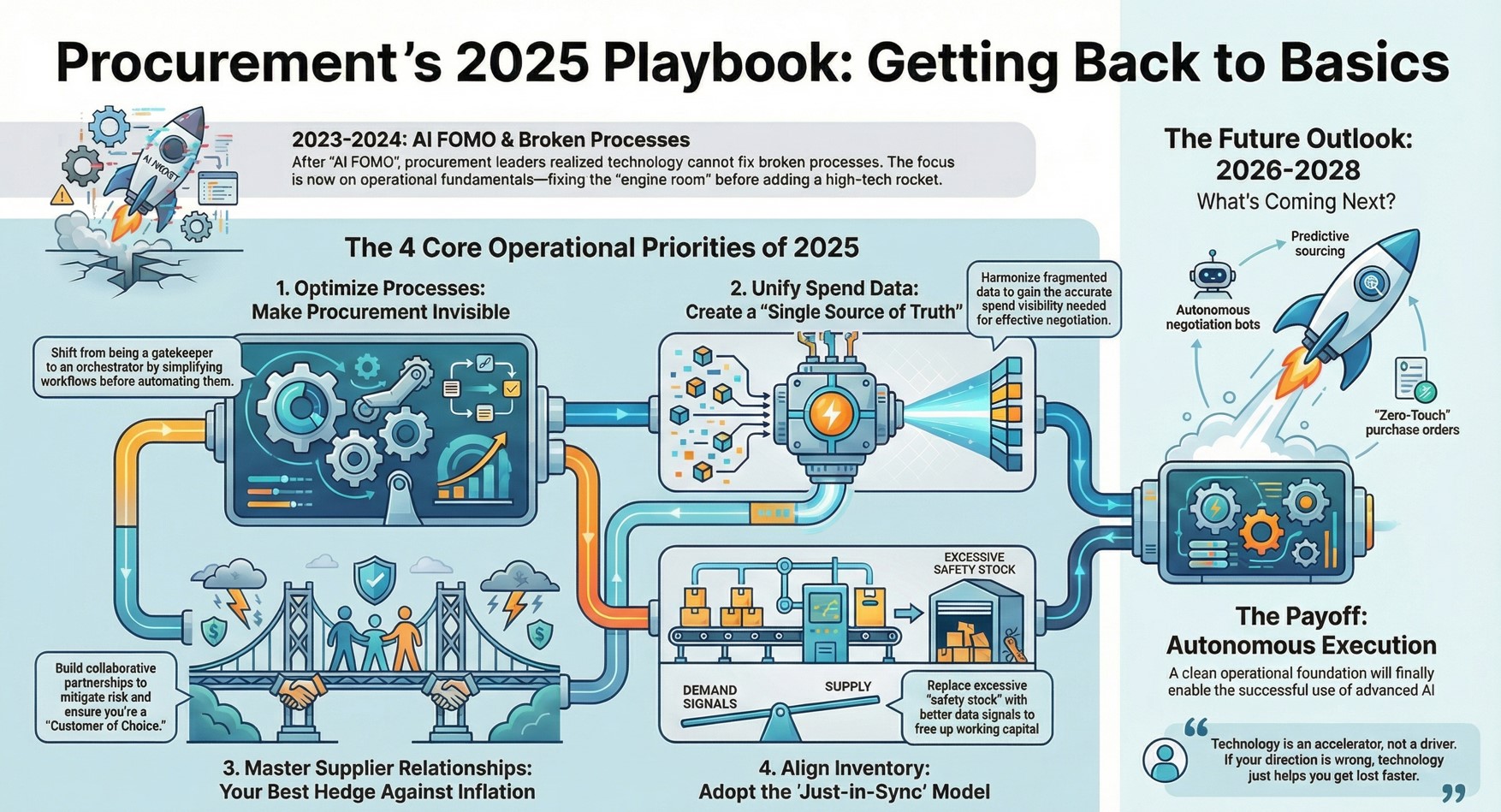

We spent 2023 and 2024 in a frenzy of "AI FOMO." We were promised that Generative AI would write our contracts, negotiate our deals, and predict the future. And while AI has begun to deliver value, 2025 taught us a humbling lesson: Algorithms cannot fix broken processes.

This year, the most successful CPOs I’ve spoken with didn’t brag about their latest chatbot. They bragged about operational excellence. They realised that to survive the geopolitical tariffs and inflation volatility that defined 2025, we had to get back to basics. We had to ensure our house was in order.

Here is what the smartest procurement leaders are actually focusing on right now, the operational priorities that are keeping the lights on and the margins healthy.

1. Process Optimization: The Return of "Invisible Procurement"

For a long time, we tried to force compliance by making procurement a gatekeeper. That failed. In 2025, the priority shifted to orchestration. The goal isn't just to "streamline" the Procure-to-Pay (P2P) workflow; it is to make it invisible.

We are seeing a move away from clunky approval chains toward "autonomous workflows" where low-risk spend is self-driving. But this only works if the process is optimised first. You cannot automate a mess. The "back to basics" approach here means rigorously defining approval routes and eliminating manual touchpoints before layering in technology.

The winners this year used process mining not just to find bottlenecks, but to redesign the user experience so that stakeholders comply because it is the easiest path, not because they are forced to.

2. Spend Transparency: From "Data Lakes" to "Data Truth"

If I had a dollar for every time a CPO told me, "I have the data, but I don't trust it," I’d have retired ten years ago.

The major operational hurdle of 2025 hasn't been collecting data; it has been harmonising it. With the proliferation of best-of-breed apps, our spend data became fragmented. The priority now is creating a "single source of truth."

Why is this critical today? Because in a high-tariff environment (which we’ve all felt painfully this year), you cannot negotiate effectively if you don't know exactly who you are spending with and where those goods originate. The latest research from PwC’s Digital Trends in Operations highlights that while we all want predictive insights, the foundational step is still accurate, categorised, granular spend visibility. Without that, your strategy is just guessing.

3. Supplier Relationship Management (SRM): Your Inflation Hedge

In the 90's, we beat suppliers up for price. In the 2000's, we ignored them until something broke. Today, SRM is our primary risk mitigation strategy.

With the volatility we've seen in commodity prices and logistics this year, contracts are becoming less about fixed prices and more about "joint value." We are seeing a renaissance in true collaboration, not just the buzzword kind.

Practitioners are actively building "Customer of Choice" programs. Why? Because when the next disruption hits (and it will), you want to be the first call your supplier makes, not the last. Recent insights from Inverto’s 2025 Trends Report suggest that companies investing in deep, collaborative SRM are seeing faster recovery times from disruptions than those treating suppliers as mere vendors. It’s about building a relationship capital account you can draw on when times get tough.

4. Inventory & Demand: The "Just-in-Sync" Model

We have finally retired the argument of "Just-in-Time" vs. "Just-in-Case." The 2025 operational standard is "Just-in-Sync."

Procurement is no longer just buying what the ERP tells it to buy. We are sitting in the demand planning meetings. We are trimming excess "safety stock" (which is just expensive fear) and replacing it with better data signals.

The focus is on inventory hygiene. We are clearing out obsolete stock that accumulated during the post-pandemic panic buying and realigning procurement cycles with actual consumption rates. It’s unglamorous work, but it releases working capital, cash that our CFOs desperately need right now. As noted in McKinsey’s Supply Chain Risk Pulse, companies are moving toward agile inventory buffers rather than massive stockpiles, using data to sense demand shifts weeks before they happen.

The Future Outlook: 2026–2028

So, where do we go from here?

If 2025 was the year of "Back to Basics," I predict 2026-2028 will be the era of "Autonomous Execution."

Once we have cleaned our data and streamlined our processes (the work we are doing now), we will finally be ready to unleash the AI agents we were promised. We will see:

- Negotiation Bots: Handling tail-spend negotiations autonomously.

- Predictive Sourcing: Systems that draft RFPs before a human even realises a contract is expiring.

- The "Zero-Touch" PO: A reality for 80% of indirect spend.

But remember this: Technology is an accelerator, not a driver. If you accelerate a car heading in the wrong direction, you just get lost faster.

A Final Thought

Don't be discouraged if your organisation isn't using "cutting-edge" AI yet. Be proud if you are fixing the approval matrix. Be proud if you are cleaning the vendor master file. Be proud if you are having coffee with a key supplier.

These "boring" operational tasks are the foundation of greatness. You are building the launchpad. The rocket comes next.

Let’s get to work.