If you’ve been in the procurement and supply chain game for as long as I have, you remember when LEAN was treated like a religion. The mantra was strict: cut the fat, reduce the stock, and chase the absolute lowest cost.

Then the world broke. Pandemics, geopolitical fractures, and the climate crisis taught us that a "skinny" supply chain is a fragile one.

But here is the controversial take I’m hearing: Lean isn't the villain. Bad implementation was.

As we settle into 2026, the smartest organisations aren't throwing the Toyota Production System out the window. They are going Back to Basics, but they are reading the manual with new glasses. The core framework, Value, Value Stream, Flow, Pull, and Perfection, remains the gold standard. However, the definitions of those words have fundamentally shifted.

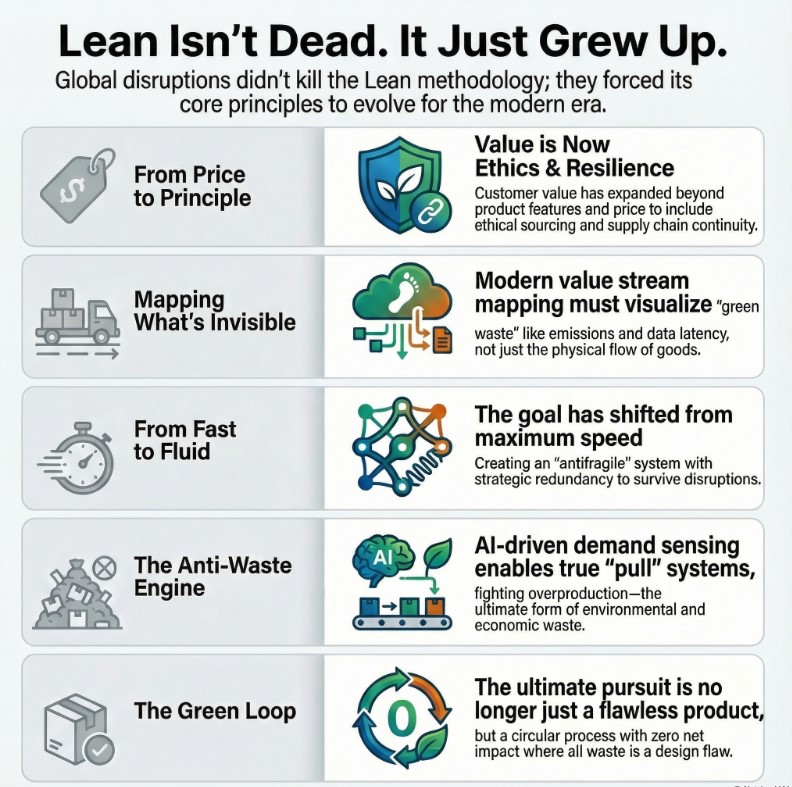

Let’s re-examine the 5 Principles of Lean for the reality of 2026.

1. Value: It’s No Longer Just About Price

Classic Definition: Define what the customer truly values and is willing to pay for.

The 2026 Reality: In the past, "Value" was synonymous with "Product Features + Price." Today, the equation has expanded. In 2026, your customer (whether a B2B partner or a consumer) defines value through the lens of Ethics and Continuity. If you deliver a widget on time, but it carries a high carbon footprint or relies on forced labor deep in the tier-n network, you haven't created value; you've created a liability.

-

The Evidence: Recent reports highlight that leading supply chains are moving beyond simple cost metrics to a “Total Value” model that explicitly measures resilience and social impact. Procurement leaders must now quantify risk mitigation as a core component of what the customer is actually buying.

2. Value Stream Mapping: Seeing the Invisible

Classic Definition: Identify all steps in creating value, focusing on eliminating waste (Muda).

The 2026 Reality: We used to map the physical movement of goods. Now, we must map the Data Stream and the Carbon Stream alongside the physical product. Modern Value Stream Mapping (VSM) exercises are uncovering "Green Waste", energy leaks, water waste, and excessive emissions.

- The Evidence: This shift is critical because, as recent data suggests, sustainability has become a built-in system requirement for logistics. If your VSM doesn't visualize Scope 3 emissions or data latency bottlenecks, it is an incomplete map.

3. Flow: From "Fast" to "Fluid"

Classic Definition: Make value-adding steps continuous and smooth, eliminating bottlenecks.

The 2026 Reality: For decades, "Flow" meant speed. Today, "Flow" means Resilience. The bottleneck isn't just a slow machine anymore; it's a closed border or a weather event. To ensure continuous flow in 2026, we are seeing the rise of "Strategic Redundancy." This is not about hoarding inventory (which hides problems); it is about decoupling critical dependencies so that if one node fails, the river finds a new path.

- The Evidence: Experts are calling this "Antifragility", the ability to improve under stress. Leading firms are now balancing cost with resilience by building "next-generation risk muscle" directly into their network design.

4. Pull: The Anti-Waste Mechanism

Classic Definition: Produce only what is needed, when it's needed, triggered by actual demand.

The 2026 Reality: "Push" systems are the enemy of the planet. Overproduction is the ultimate form of waste because it consumes energy and raw materials to create something nobody wants. With the AI-driven demand sensing tools we have available now in 2026, our ability to execute a true "Pull" system is unprecedented.

- The Evidence: We are finally seeing AI move from "analyst to operator," where predictive AI automates replenishment based on real-time consumption rather than historical guesses. This allows us to align production triggers closer to reality than ever before.

5. Perfection: The Infinite Green Loop

Classic Definition: Constantly strive to improve processes (Kaizen) to get closer to perfect delivery.

The 2026 Reality: "Perfection" used to mean Zero Defects. Now, it means Zero Net Impact. The pursuit of perfection is driving the Circular Economy. We are seeing a massive trend where "Waste" is viewed simply as a design flaw. Procurement is collaborating with R&D to design products that can be disassembled and remanufactured.

- The Evidence: This is no longer optional. With the EU Digital Product Passport (DPP) rolling out for key sectors between 2026 and 2030, the transparency required to prove "circularity" is becoming a legal license to operate.

Future Outlook: The "Legislative Tsunami"

Looking at the next three years (2026-2029), these 5 Principles will be your shield against the incoming "Legislative Tsunami."

As Digital Product Passports (DPP) become mandatory across the EU and North America, the transparency required by Value Stream Mapping will become a compliance necessity, not just a nice-to-have. The organisations that have mastered Flow (data visibility) and Pull (efficient resource use) will navigate these regulations with ease. Those stuck in legacy "batch-and-push" models will drown in compliance costs.

Conclusion: Your "Monday Morning" Plan

The beauty of Lean is its simplicity. It strips away the noise. As you look at your strategy for the year ahead, don't get distracted by the flash of new tech. Go back to the 5 Principles.

Ask your team:

- Value: Do we know what our customer actually cares about today?

- Stream: Have we mapped the carbon in our process?

- Flow: Where are we fragile?

- Pull: Are we making things nobody bought yet?

- Perfection: How do we close the loop?

Lean isn't dead. It just grew up. Let's get to work.