Introduction: From Risk Management to Resilience by Design

The lexicon of supply chain management is due for an upgrade. The term "risk management" has become obsolete, as it implies a defensive posture against occasional, predictable threats. The reality of 2026 is one of constant, multi-faceted disruption, an environment that demands a proactive and strategic approach best described as "resilience by design". The goal is no longer simply to withstand shocks but to build supply networks that are inherently robust, agile, and even antifragile—capable of emerging stronger from volatility. This shift reframes resilience not as a cost center to be minimized, but as a critical source of competitive advantage and a core tenet of modern procurement strategy.

The Current Landscape: A Web of Interconnected Threats

The imperative for resilience is driven by a high-stakes operational environment where vulnerabilities can emerge from any direction and cascade through the global supply network with devastating speed.

Disruption as the New Normal

The frequency, variety, and impact of supply chain disruptions have escalated to the point where they are no longer exceptional events but a constant operational reality. CEOs now consistently rank supply chain issues as a top-three risk to their business, a significant elevation in prominence from just a few years ago. The data supports this perception: one study found that over 76% of European shippers experienced supply chain disruptions throughout 2024, with nearly a quarter reporting more than 20 distinct disruptive incidents in that year alone. These are not isolated "Black Swan" events; they are the recurring, predictable consequence of a highly interconnected yet fragile global system.

The Visibility Black Hole

A primary source of this fragility is the pervasive lack of visibility beyond direct, Tier 1 suppliers. While most organisations have robust processes for managing their immediate commercial relationships, very few have equivalent oversight of their suppliers' suppliers. This "visibility black hole" is where many of the most significant risks lie dormant, from exposure to geopolitical flashpoints and human rights violations to dependencies on single-source sub-component manufacturers. Without deep-tier visibility, true risk assessment is impossible, leaving organisations perpetually in a reactive state.

The Digital Battlefield

The digital transformation of supply chains has created enormous efficiencies, but it has also opened up a new and dangerous frontier for conflict. Cybersecurity is no longer an ancillary IT concern; it is a fundamental and urgent supply chain risk. State-aligned threat actors and sophisticated criminal organisations are actively targeting the digital infrastructure that underpins global commerce, from port operating systems and logistics platforms to financial payment networks. The supply chain itself has become the primary vector for attack. Analysis shows that nearly one-third of all corporate data breaches in 2023 originated through third-party access, meaning a vulnerability in a supplier's network can become a direct gateway into a buyer's most critical systems.

Strategic Implications and Necessary Responses

The traditional procurement playbook, optimised for cost and efficiency in a stable world, is dangerously inadequate for this new landscape. Building true resilience requires a fundamental rethinking of how risk is measured and a convergence of historically separate functions.

The analytical framework used to make sourcing decisions must evolve. For decades, procurement has been optimised around metrics like Total Cost of Ownership (TCO), which seeks the lowest possible cost under assumed stable conditions. However, in an era of constant disruption, the costs associated with these disruptions, premium freight, lost production runs, reputational damage, and lost sales, are massive and often unquantified. Strategies that build resilience, such as qualifying a second source or holding strategic inventory, often appear more expensive when viewed through a narrow TCO lens, leading to their rejection. This framework is flawed because it fails to price risk correctly. Leading organisations in 2026 will abandon this outdated model in favor of a "Total Cost of Risk" (TCOR) approach. This advanced analytical model will quantify the expected financial impact of disruptions in a high-risk supply chain and compare it to the cost of a more resilient, albeit potentially higher, TCO, alternative. This reframes resilience not as an optional "extra cost" but as a direct, measurable, and often highly positive ROI investment in protecting revenue and margin.

This new risk landscape also forces the convergence of two historically siloed functions: supply chain management and cybersecurity. In the past, supply chain risk was primarily concerned with physical flows—ports, factories, and trucks—and the operational and financial viability of suppliers. Cybersecurity, meanwhile, was the domain of the Chief Information Security Officer (CISO) and focused on protecting the enterprise's internal network. Today, the data clearly shows that the biggest cyber threats are infiltrating organisations through the supply chain via trusted third-party vendors. A ransomware attack on a critical logistics provider or a key component supplier can shut down a company's production just as effectively as a hurricane or a factory fire. Consequently, one cannot have a resilient supply chain without having a cyber-secure supply chain. This reality will force a merging of responsibilities between the CPO and the CISO. By 2026, leading companies will have created integrated "Supply Chain Resilience & Security" teams, established joint CPO-CISO governance committees, and embedded rigorous cybersecurity audits as a standard, non-negotiable part of the supplier qualification and ongoing performance management process.

The Three Pillars of Modern Resilience

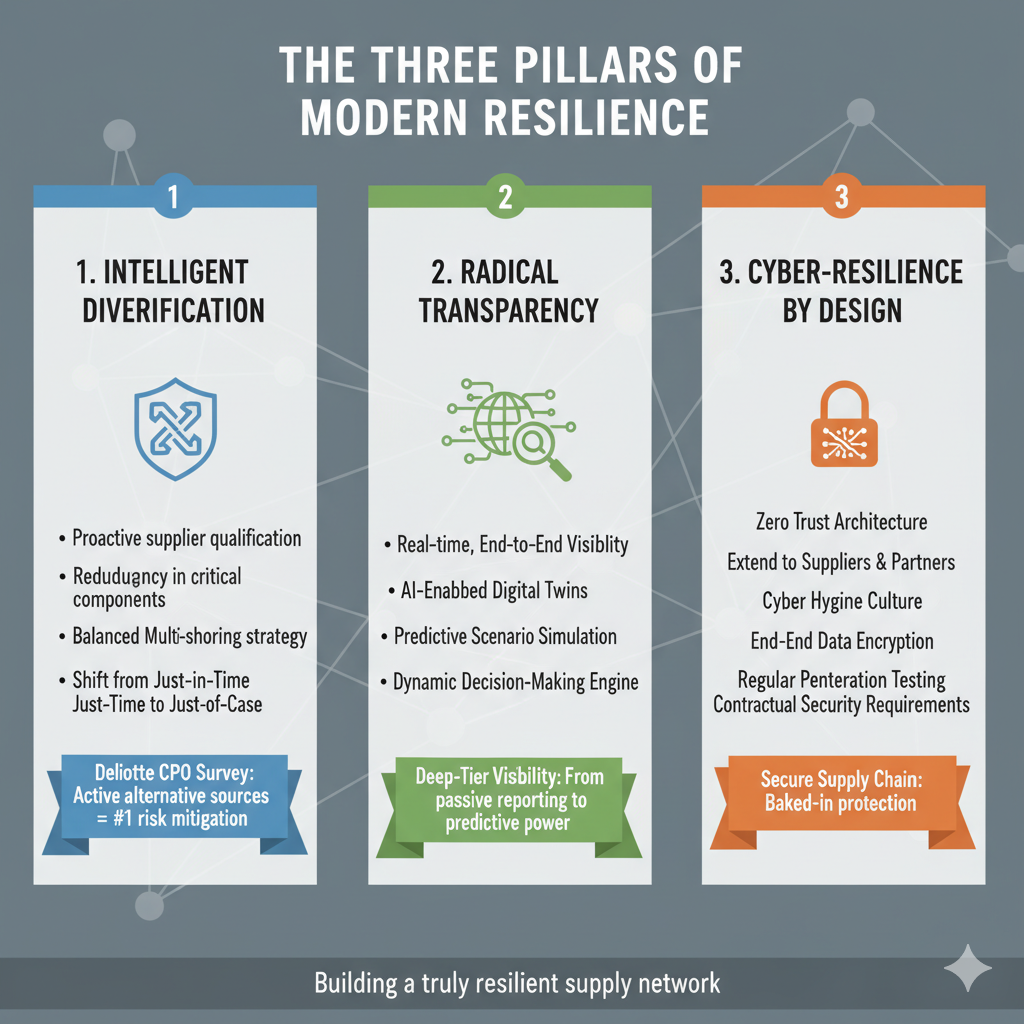

Building a truly resilient supply network requires a multi-faceted strategy grounded in three core pillars: intelligent diversification, radical transparency, and cyber-resilience by design.

Pillar 1: Intelligent Diversification

This pillar moves beyond the simplistic idea of having a single backup supplier. True diversification is a proactive strategy that involves qualifying new suppliers in advance of need, systematically building redundancy into the supply chains of critical components, and employing a balanced multi-shoring strategy to increase overall network reliability. As confirmed by Deloitte's CPO survey, maintaining active alternative sources is the single most effective risk mitigation strategy. This represents a deliberate and strategic shift from a "just-in-time" philosophy, optimised for inventory reduction, to a "just-in-case" model for the components and materials that are most critical to business continuity.

Pillar 2: Radical Transparency

Achieving deep-tier visibility is impossible without leveraging technology. Investing in platforms that provide real-time, end-to-end visibility across the entire supply network is no longer a luxury but a necessity. The most advanced organisations are moving beyond simple track-and-trace solutions to deploy AI-enabled Digital Twins. These sophisticated virtual models of the supply chain provide visibility into Tier-N suppliers, allow leaders to simulate the impact of various disruption scenarios (e.g., a port closure, a supplier bankruptcy), and evaluate the effectiveness of different mitigation options in real time. This transforms visibility from a passive, historical reporting tool into a dynamic, predictive decision-making engine.

Pillar 3: Cyber-Resilience by Design

A resilient supply chain must be a secure one. This requires extending modern cybersecurity principles, such as Zero Trust architecture, beyond the enterprise's own digital perimeter to encompass key suppliers and partners. It also necessitates baking "cyber hygiene" into the company culture, ensuring that every employee who interacts with the supply chain understands their role in protecting it. Operationally, this means implementing layered technological protections, including end-to-end data encryption and regular penetration testing of supplier systems. From a procurement perspective, the role is to ensure these stringent security requirements are explicitly written into supplier contracts, continuously monitored, and regularly audited for compliance.

Future Outlook and Call to Action

By 2026, standard supplier performance scorecards will have evolved to include a mandatory and heavily weighted "Resilience Rating." This composite score will assess suppliers on critical factors such as their geographic concentration, their ability to provide deep-tier visibility, their financial stability, and the maturity of their cybersecurity posture.

To enable this, CPOs must make a compelling business case for investment in a unified resilience platform. Such a platform would break down existing silos by integrating threat intelligence across geopolitical, cyber, climate, and financial domains, providing a single, holistic view of supply chain risk.

The immediate call to action is to test the organisation's current resilience. Leaders should conduct a "war game" exercise that simulates a plausible, high-impact scenario, such as the simultaneous bankruptcy of a critical sole-source supplier and a major cyberattack on a key logistics partner. By mapping the response process in detail, teams can identify the hidden blind spots, communication breakdowns, and decision-making bottlenecks that would cripple the organisation in a real crisis. This exercise will provide the empirical evidence needed to justify the investments in people, processes, and technology required to build a truly unbreakable chain.